Parm.

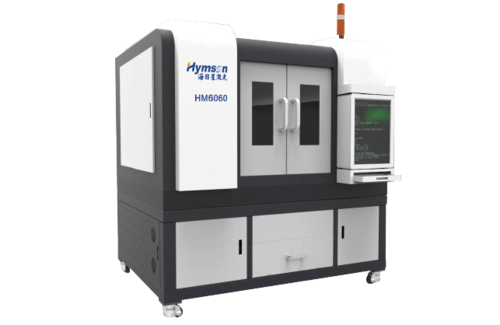

| Laser Resonator | ||||

| Type | Fiber Laser | |||

| Power(W) | 3000~12000 | |||

| Features | ||||

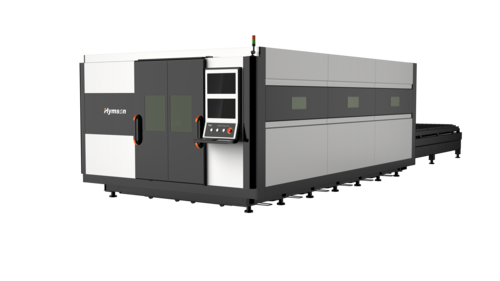

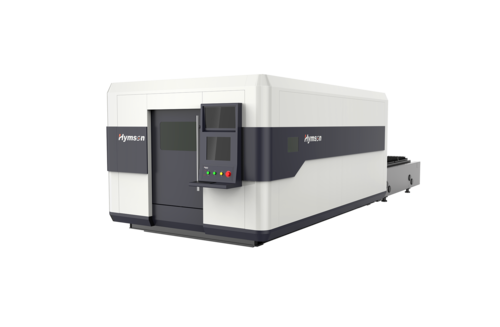

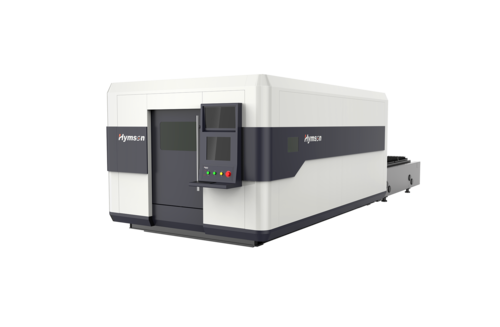

| Model | HF3015H | HF4020H | HF6020H | HF6025H |

| Working Range(mm2) | 3000 x 1500 | 4000 x 2000 | 6000 x 2000 | 6000 x 2500 |

| Weight(kg) | 8700 | 12000 | 17000 | 19000 |

| Max. Work-piece Weight(kg) | 800 | 1000 | 2600 | 3000 |

| Dimensions(mm) | ||||

| Length | 8500 | 10500 | 15000 | 14700 |

| Width | 5700 | 5750 | 6400 | 6800 |

| Height | 2450 | 2450 | 2550 | 2550 |

| Max. Work-piece Thickness(10000W) | ||||

| Mild Steel | 30mm | |||

| Aluminum | 50mm | |||

| Stainless Steel | 50mm | |||

*Please contact us for more detail information via email: info@gzhymson.com. Thank you.

Mgt.

| CNC System |

|

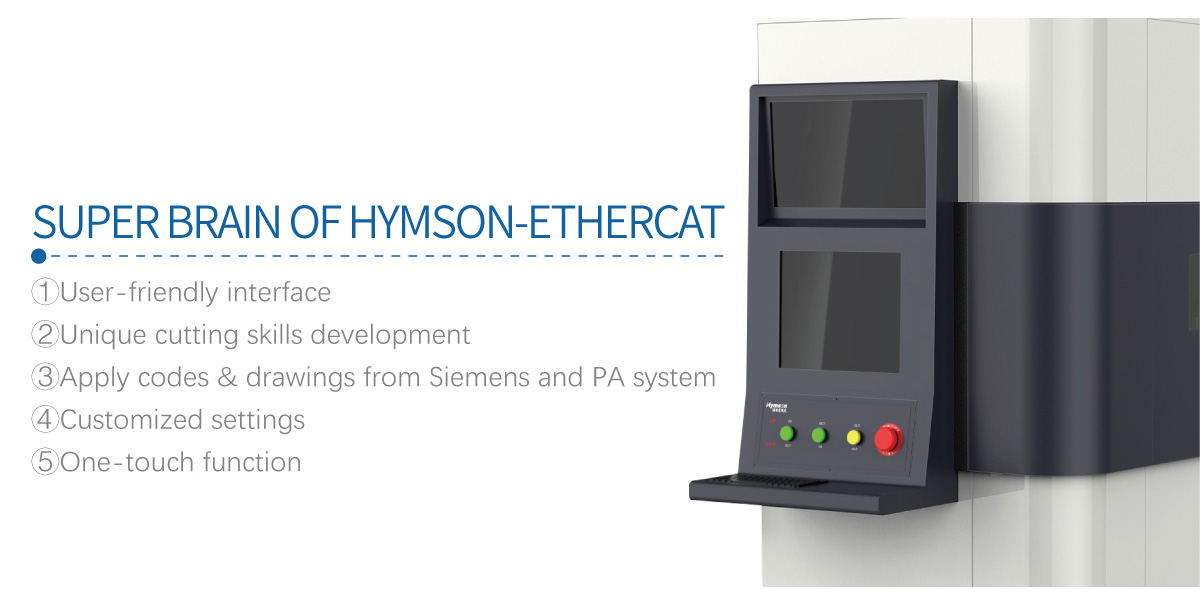

The equipment uses Beckhoff CNC cutting system, equipped with a large screen display, and it’s a professional laser cutting system. Based on Windows operation system, Beckoff integrates a lot of laser cutting modules with special functions. Equipped with a wireless keyboard and mouse, the operation is simple and easy. In order to facilitate the work of the operator, a space is reserved below the display for storing consumables and professional tools. The console has two USB connectors that can be used to connect removable memory devices such as flash drives to download drawings and programs. In addition, the machine also has a LAN connector for integrating the machine into a common network infrastructure. |

| Software |

|

We provide fully functional CNCkad cutting software. This software is a complete set of integrated sheet metal CAD/CAM automatic programming software from design to production, with rich functions, high degree of simplification and optimization of the cutting process, and a significant increase in operator efficiency and productivity. Engraving and cutting mode automatic switching function The engraving and cutting modes are set individually by the operator before the cutting starts. The operator can reconfigure the machine and enter new settings without having to stop the material handling process. Switching between modes occurs automatically, which increases the productivity of the cutting complex The operator sets up before the start of processing and does not need to stop the material handling during processing Graphic operation function CNCKAD is a complete set of integrated sheet metal CAD/CAM automatic programming software from design to production.Supports the CNC operation of the entire process of the equipment, including drawing, automatic or interactive processing, post processing, CNC program simulation, manual and automatic nesting, NC file download and upload Real-time frequency and power curve In order to obtain high-quality acute and right angles, the software is equipped with real-time frequency and power curves, and the power of the laser radiation is automatically adjusted according to the speed of movement of the cutting head.When the cutting head is at zero speed (at the time when the corner is stopped), the output radiant power is equal to the minimum power set in the setting to prevent burnout of the corners Technology Library

The software has its own dedicated process library, and it selects the corresponding material library parameters according to different materials, and it is convenient to modify the storage operation. Supports multiple files It can directly input graphic files generated by famous CAD software such as Autocad,SolidEdge, SolidWork and CadKey. The software supports many different numerical control devices. It can generate NC files for different parts from one part,and can be used when multiple parts are machined at the same time. User-friendly graphical interface h better than a set of numbers, so setting up such a device would be more enjoyable and the adjustment itself would be much faster Rich process layer interface TwinCAT provides 16 layers, and each layer can be individually set including cutting speed, laser power, air pressure, cutting height and other process parameters. The color of each layer is unique, which is convenient for browsing and configuring cutting graphics parameters Simple software The simplicity of TwinCAT software allows you to shorten the basic work of learning machines.The software integrates a variety of laser cutting modules with special functions. The interface is user-friendly and easy to operate. This will have a positive impact on production costs. TwinCAT software also offers free upgrades |

| Automatic Focus Control |

|

Optical path adaptive system: cutting head has adaptive optical system, the focus is automatically adjusted to ensure that the focal point of the stable switching focus during the cutting process.It is especially important for the cutting of thick plates to ensure the consistency of the cutting quality throughout the processing area. |

| Automatic Height Control |

|

The system is equipped with a non-contact capacitive sensor as standard, which ensures a constant distance between the nozzle and the processing material. Even if the workpiece surface is uneven, it has a perfect processing effect. The automatic height system implements the following functions When the material burns, the optical head rises to the jump height set by the operator.As the head is raised, the metal melt does not fall on the nozzle part, and cannot be derived or the whole optical head fails. Cut further from the set distance Cutting on the fly. This method can significantly reduce the processing time of the plate, because it does not cut every detail individually, but cuts all the outlines into a straight line. The high-speed optical head delivers the entire sheet line by line, cutting out the contours of the corresponding segments. It is particularly time-saving to cut the perforated grid. |

Opt.

|

Gas Management |

|

|

Compressor |

Screws, air-cooled, with sound-insulated housing, receiver, desiccant, and ancillary equipment for air cutting up to 16 atmospheres. |

|

Vertical low-temperature gasifier |

. |

|

Safety |

|

|

Operator safety glasses |

|

|

Smoke Removal |

|

|

Exhaust fan |

Used to remove the combustion products produced during the cutting process. |

|

Filter - Ventilation |

Filters - Ventilators are designed to remove suspended, fine and moderately dispersed dust and smoke from air during welding, metal thermal cutting, etc. |

|

Spare Parts |

|

|

Supplies accessories |

Protective glasses, nozzle. |

Sample

|

|

| 25MM MS | 20MM MS |

|

|

| 20MM SUS | 10MM AL |