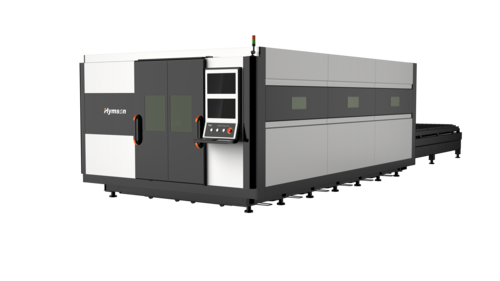

HP · D Series

产品概览

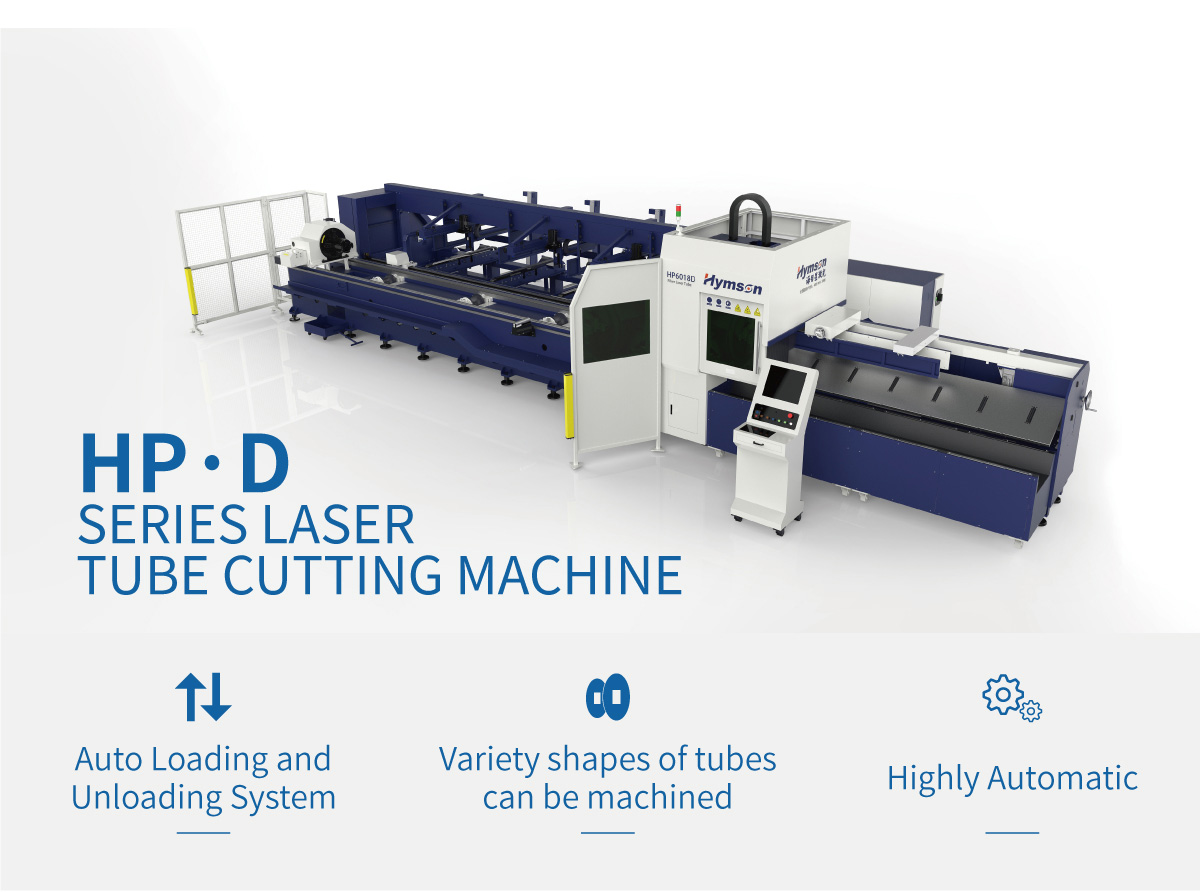

The new HP·D series laser tube cutting machine is an expert-class ultra-high speed intelligent machine tool.

Automatic loading and unloading platform, high-speed tube change, easy renewal cutting, ensure long-term efficient operation.

Double-acting pneumatic chuck, high-precision positioning, can cut a variety of tube type with different thicknesses.

HP·D has a highly automated, five-axis linkage, ultra-fast rotation, movement and high-precision positioning, enabling 24-hour stable cutting.

Parm.

| Features | |

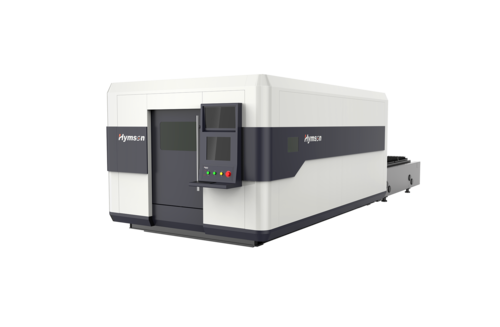

| Model | HP6018D |

| Weight(kg) | ≤20000 |

| Specification(mm) | |

| Length | 12550 |

| Width | 6020 |

| Height | 2800 |

Please contact us for more detail information via email: info@gzhymson.com. Thank you.

Mgt.

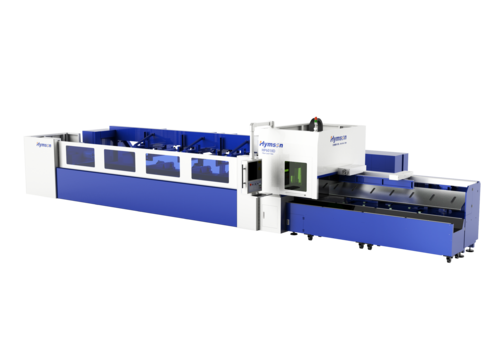

HP · D Series Tube Laser Cutting Machine#

Control System

The equipment uses Beckhoff CNC system, equipped with a large screen display and professional laser cutting system. Based on the Windows operating system development, the cutting platform integrates a lot of dedicated laser cutting system. It’s also equipped with a wireless keyboard and mouse which enables the cutting operation is simple and easy.

In order to facilitate the work of the operator, a space is reserved below the display for storing consumables and professional tools. The console has two USB connectors that can be used to connect U disk and other removable memory to download drawings and programs. In addition, the machine also has a LAN connector for integrating the machine into a common network infrastructure.

Software

RADAN is a professional sheet metal design and processing software from Planit. Planit Software Ltd. is a world-renowned supplier of manufacturing information software products. It supports collision detection to make cutting more safe and efficient, and graphic simulation can provide three-dimensional panoramic viewing of the edited workpieces. Automatic sorting / manual sorting of the cutting path, single pipe / multiple pipe nesting and other functions are also available.

Engraving And Cutting Mode Automatic Switching Function

The Engraving and cutting modes are set individually by the operator before the cutting starts. The operator can reconfigure the machine and enter new settings without having to stop the machine. Switching between modes occurs automatically, which increases the productivity of the complex materials cutting.

The operator sets up before the start of machining and does not need to stop the machine.

Real-time Frequency And Power Curve Control

In order to obtain high-quality sharp corners and chamfers, real-time adjustment of power, pulse duty cycle, and frequency is performed at the cutting corners through real-time frequency and power curve control. When cutting the chamfer, it is ready to enter the chamfer. Part of its power, duty cycle adjustment, after the completion of chamfer cutting to restore the cutting state. In the meanwhile, it can achieve sharp angle cutting and chamfer cutting at the same time to acquire the desired effect.

Technology Library

Beckhoff has its own dedicated technology library. According to different materials, users can select the corresponding material library parameters, and modify the storage operation.

Supports Multiple Files

It can directly input graphic files generated by well-known 3D drawing software such as Pro/E, UG, solidworks, 3Dmax, Auto CAD, etc. The software supports a variety of different numerical control devices and can generate NC files for different systems from one part for multiple devices at the same time when machining a part.

User-friendly Graphical Interface

In order to quickly set up the device, a convenient graphical interface can be used. Graphical information is considered to be much better than a set of numbers, so setting up such a device would be more enjoyable and the adjustment itself would be much faster.

Abundant Process Layer Interface

TwinCAT provides 16 layers, and each layer can be individually set including cutting speed, laser power, air pressure, cutting height and other process parameters. The color of each layer is unique, allowing you to browse and configure the cutting graphics parameters.

User-friendly Software

The simplicity of TwinCAT software allows you to shorten the basic work of learning machines. The software integrates a variety of laser cutting modules with special functions. The interface is user-friendly and easy to operate. This will have a positive impact on production costs. TwinCAT software also offers free upgrades.

Follow-up control function functions, the Z-axis follow-up and the G-code are executed synchronously, which gives the G-code movement speed during idle movement, thereby increasing the speed of the machine itself, and greatly improving the production efficiency.

Pipe Bending Center Correction Function

The correction function of the bending pipe center makes the center pipe offset function for the three kinds of regular pipe materials such as square pipe, rectangular pipe and waist pipe to ensure that the profile is centered on the surface of the pipe and reduces the asymmetry of both sides of the profile caused by pipe bending.

Opt.

| Gas Control | |

|

Compressor |

Air-cooled, with acoustic enclosure, receiver, desiccant, and ancillary equipment for air cutting up to 16 atmospheres. |

| Spaer Parts | |

|

Accessories |

Goggles, Nozzle。 |

Video

1mm stainless steel 3000w

Round tube cutting round holes

Round tube cutting hive shape

Round tube cutting "U" shape

Square tube cutting square holes

Square tube cutting"Hymson"

HP-D Tube laser cutting machine-loading and unloading system